INPRO is dedicated to serving our customers’ needs, whatever they may be. In recent years, we’ve seen an increasing need to treat, coat, and cure complex 3D objects. To address this need, INPRO expanded its integration toolbox to include robot arms with our robotic integration capability. We can integrate any of our technologies with a robot arm, as well as integrating an arm to other common tasks, like pick-and-place applications, machine tending, part finishing, assembly, and more.

Low Hanging Fruit

Ripe for automation

Machine Tending

Cobots excel in machine tending applications and serve to extend the useful life of older machines that previously required an operator. Cobots allow for integrating old machines into modern assembly lines, with the cobot acting as an adapter. They also lessen the burden on machine operators, enabling a single operator to run multiple machines at once without spending valuable time on simple tasks like part loading and unloading.

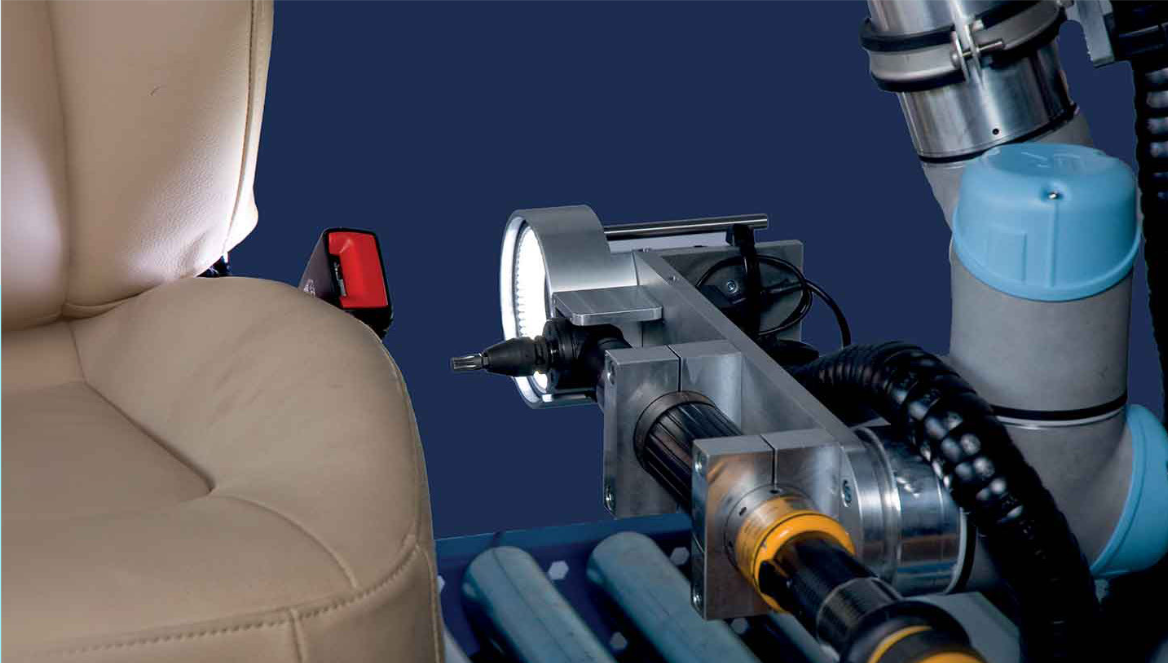

Assembly

Some assembly tasks (eg. screwing, pressing in bearings, etc.) are readily automatable with a robot arm. If placed near human assemblers, a cobot can be a valuable addition to the team, increasing efficiency by splitting the workload to what each does best.

Finishing

Finishing is a popular use for robot arms in manufacturing. Companies find that the accuracy and repeatability of robot arms works really well for this task. Removing operator inefficiencies from manual finishing tasks like sanding, buffing, or polishing can drastically increase the throughput of a particular finishing process.

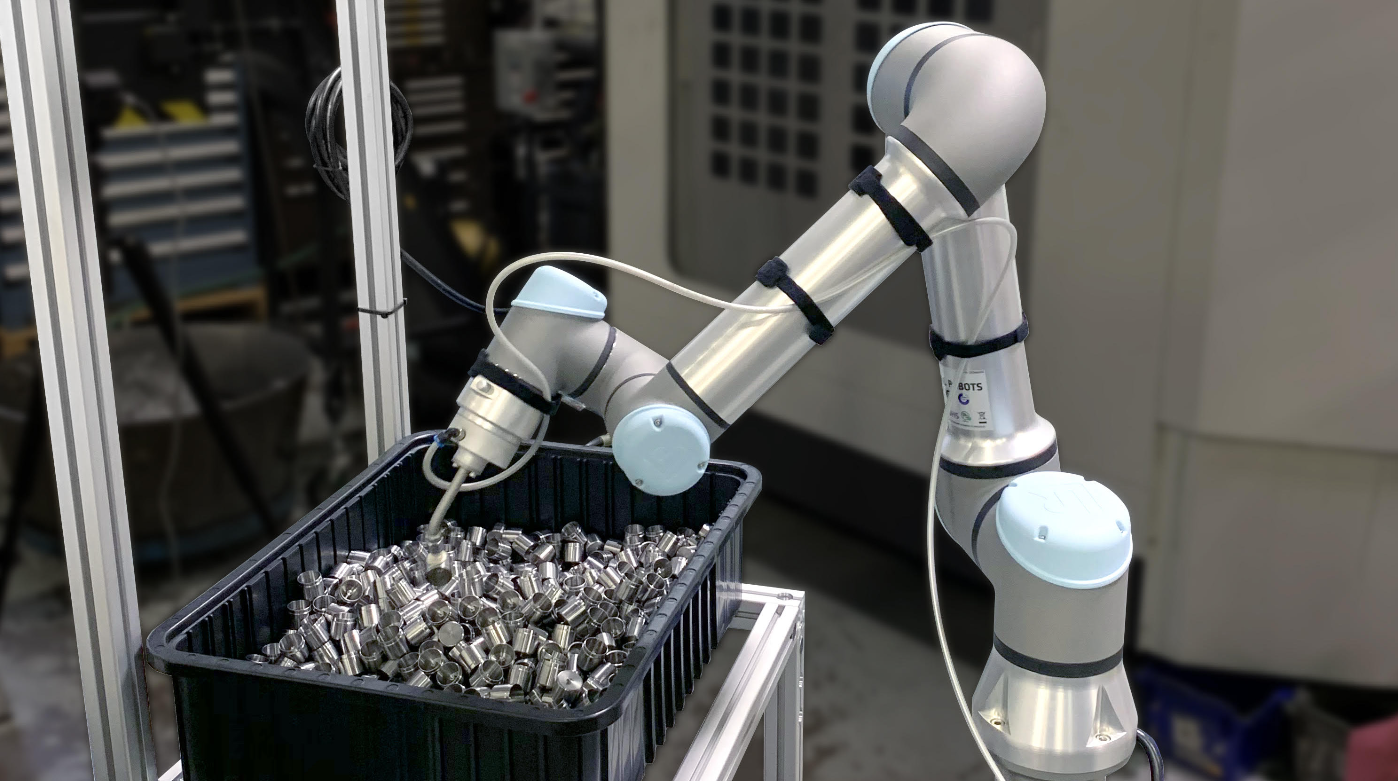

Material Handling

Bin picking, packing, palletizing, kitting, etc. are quite repetitive processes and getting a dedicated custom solution can be costly. Cobots can be used for highly tailorable solutions, while remaining flexible to be deployed in a separate area later. Innovative products like UR’s ActiNav technology enable even random, unsorted bins to be automatically unloaded to feed downstream processes when properly integrated by a knowledgeable robotic system integrator.

Industrial Robots or Cobots?

Industrial Robots

What Are They?

When you think of robot arms, generally what comes to mind are the large heavy-duty robot arms used in places like an automotive manufacturing plant. These are called industrial robot arms, and they’re characterized by their high payload capabilities, high acceleration, and top speed. Not all are huge though, as some models sport much lower payloads for given applications. However, because of their strength and speed, they need to be caged or otherwise protected from human operators due to safety concerns. In addition, programming these robots isn’t straightforward for typical manufacturing plant personnel and usually requires more specialized training and practice. These robot arms are intended as critical components in highly specialized and engineered manufacturing applications where reduced cycle time and higher throughput requirements demand the unmatched speed of industrial robots.

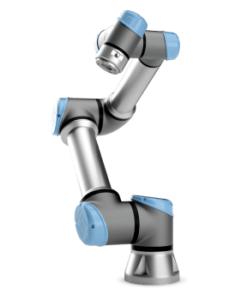

Cobots

What Are They?

In the past couple decades, a new type of robot arm arrived on the scene: the collaborative robot, commonly dubbed the cobot. As opposed to being isolated in a corner, cobots are designed to work side-by-side with human workers, alleviating the small monotonous tasks and allowing the operator to focus on more nuanced tasks. As a part of this package, the method of programming is much more intuitive, making a cobot much more easily adoptable by both large manufacturers and small businesses alike. Cobots are ideal for applications such as machine tending, material handling, and some assembly tasks, since they can be placed right where a human would have stood, without any restrictive cages or having to section off a large amount of floor space.

What Are Their Strengths?

- High Payload

- Better Accuracy

- Speed and acceleration

What Are Their Strengths?

- Can work side-by-side with humans without guarding

- Relatively easy to program for simple tasks

- Built-in force sensitivity

Common Applications

Industrial robots and collaborative robots are commonly found in all sorts of applications. INPRO specializes in UV curing surface treating applications, and offers unique expertise in integrating robots for other applications as well.

- Machine tending

- Packaging

- Kitting

- Assembly

- Welding

- Drilling

- Palletizing

- Painting

INPRO is a Certified System Integrator for Universal Robots, so we are uniquely qualified to aid in your robotic automation application. However, we pride ourselves on always trying to help customers select the right system architecture and manufacturing technology for their specific process needs, which may mean a automated robotic arm system or completely custom robot machine build. If what’s needed is a capability not currently offered by UR or our other partners, we can work with you to determine what is best suited for your application and help you achieve that goal.