Trans Mountain has proactive programs to identify all hazards that could affect pipeline safety and then to monitor and assess for the presence of these hazards with a goal of preventing pipeline failures. Here’s a summary of the measures we use to prevent and monitor common pipeline hazards:

Corrosion Protection

All pipelines have a corrosion resistant external coating and are further protected with impressed current cathodic protection systems in the event of a coating defect. We remotely monitor the cathodic protection and collect and analyze the data collected to ensure the pipeline is effectively protected.

Internal Inspection Tools

Internal inspection tools, or smart pigs, form the foundation of anomaly detection investigation and pipeline repair programs. Some of tools use technologies similar to the ones used in medical imaging devices and they are used to detect a variety of pipeline defects. Magnetic Flux Leakage (MFL) tools (shown in illustration above) detect metal loss from corrosion. Caliper or ultrasonic tools detect corrosion related metal loss as well as mechanical damage such as dents and gouges. Shear wave ultrasonic and Electro-Magnetic Acoustic Transmission (EMAT) tools are used for crack detection.

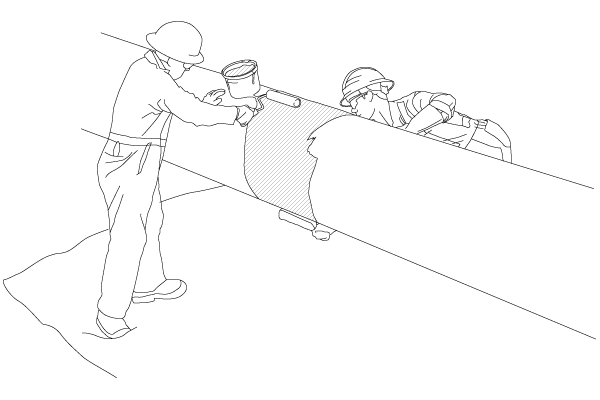

Integrity Digs

Integrity digs are typically based on the results of an inline inspection using a smart tool. An integrity dig involves a segment of pipe being excavated and inspected using non-destructive examination methods. If required, repairs are completed, the site is backfilled and restored to the original condition or better.

Integrity digs require careful planning and preparation, including conducting environmental assessments, obtaining approvals and permits from landowners, Indigenous groups, and municipal authorities.

Our goal is to ensure that our pipelines continue to operate safely and reliably while minimizing the impact of this work on both the public and the environment and complying with all applicable standards and regulatory requirements.